This is Part 2 of the article started previously in Mootori. Huss continues his comparison of Evinrude and Archimedes outboards.

However, the Evinrude engine, as well constructed as it was in many respects, was comparatively inferior in detail. The counterweight, which balances the parts moving back and forth, and which should have been located opposite them, i.e. in the knees of the crankshaft on the opposite side of the crank pin, was also adapted to the flywheel.

Because the latter was located very far away due to the long bearing structure, it naturally created unnecessarily strong vibrations when the engine was running, which in a thin and light boat often caused such an echo that the boat began to shake violently. I dare not suppose ignorance to have been the cause of this unfavorable design. Guessing — here, as in many other cases, the right design had to give way to the cheaper one.

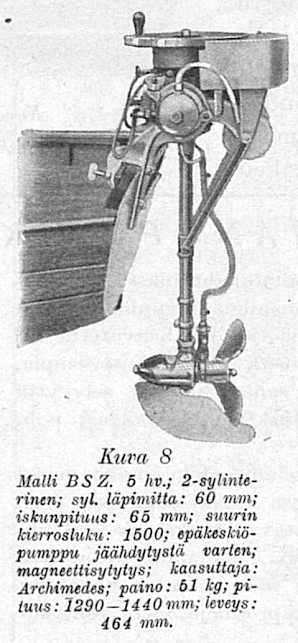

However, it is impossible to achieve perfect balancing in single-cylinder engines without using additional machinery. Theoretically speaking, in order to build a perfectly balanced engine, it is still not necessary to carry out the division into several cylinders. The kind of two-cylinder model that the French call »moteur eguilibre» fulfills the intended ideal, albeit with this engine, at least in the original design, is an unnecessarily complicated piece of machinery. In the two-cylinder engine last mentioned and shown in outline in Fig. 4, the reciprocating masses balance each other perfectly.

In reality, absolute balancing cannot be achieved, because some disproportionality always remains, no matter how carefully the machine's cylinder is built.

Creating a high-speed, vibration-free engine was the goal of the builder of the "Archimedes engine", when he chose an engine whose cylinders are evenly opposed and pistons move in opposite directions.

The relatively complex shaft belonging to the motor shown in Figure 4 has been abandoned here, sacrificing a bit of the possibility of balancing, and it has been replaced by the two-knee shaft according to Figure 5. This shows the old fashioned Archimedes engine, cut in half.

Between the oldest models of the Archimedes engines and the Evinrude engine, there was hardly any more essential difference as far as the rest of the machinery is concerned, but over time a whole series of interesting and appropriate structures have given this a design aimed at perfection for the engine. I would like to mention a few of the most significant details of this development.

Archimedes was probably the first outboard motor that was freed from battery ignition hindered by various shortcomings and equipped with a high-voltage magneto. This device was fitted to a stand that could be moved around the axis, so that the setting of the ignition could be done by moving the magnet along with the stand. With this design of the mag a strong spark was still obtained from the net device, when the device was rotated to a position corresponding to both late ignition (when starting) and early ignition (as is well known, this is not the case with ``Bosch'' magnetic devices operating with a standard ignition layout).

After the war, no magnetic device could be obtained from Germany, which caused A-B Archimedes started his own manufacture of these instruments. The form then chosen was what is now called a flywheel magneto (because the steel magnet of the magnetic device is attached to the flywheel of the engine), and it may be interesting to hear in this connection that the Archimedes flywheel magneto actually gave rise to the excellent flywheel magneto which manufactured by the world-famous company name Robert Bosch, in Stuttgart.

A weakness that was common both to the old-style Archimedes engine and to most other outboard engines, but which has been corrected in the newer models of this engine, deserves to be mentioned.

The cooling water pump placed in the gearbox, kept running by the eccentric, started to leak regularly after being in practice for a long time, due to wear of the piston. The water was then able to penetrate past the worn piston into the gearbox housing, causing the lubrication of both the heavily loaded gear and especially the bearings of the propeller shaft and drive shaft to deteriorate. But if that's not enough, the water penetrated upwards into the pipe surrounding the drive shaft as well. The pipe had to be equipped with holes so that the water could escape when it penetrated upwards, because otherwise it could have penetrated into the engine's crankcase and interrupted the engine's operation.

For this reason, the cooling water pump models in newer models are placed outside the gearbox, as shown in Figure 6. The eccentric that uses the pump is surrounded by a pockenholz ring, which, as is known, needs no other lubrication than water, in which it moves all the time.

Some models of the »Archimedes» engine are equipped with a convenient take-back device and a device that automatically sets the rudder arm in a position corresponding to the straight travel direction.

The Archimedes engine, which was based on the Swedish engineers O.W. Hult and C. A. Hult patent, and manufactured by Aktiebolaget Archimedes, Stockholm, was put on the market relatively soon after the Evinrude engine began to gain popularity in Europe. With its many excellent features, the Archimedes motor soon conquered the market all over the world, soon becoming the leading brand in the world market.

In addition to the determined work of the factory's leading technicians, this has probably been influenced by the precise selection of materials, the quality of the company's available machines and tools and, last but not least, the precise work of the factory's convenient and skillfully trained workforce.

No comments:

Post a Comment